The refrigeration racks installed at the Beijing National Speed Skating Oval will be manufactured by PROFROID

Mainland China -

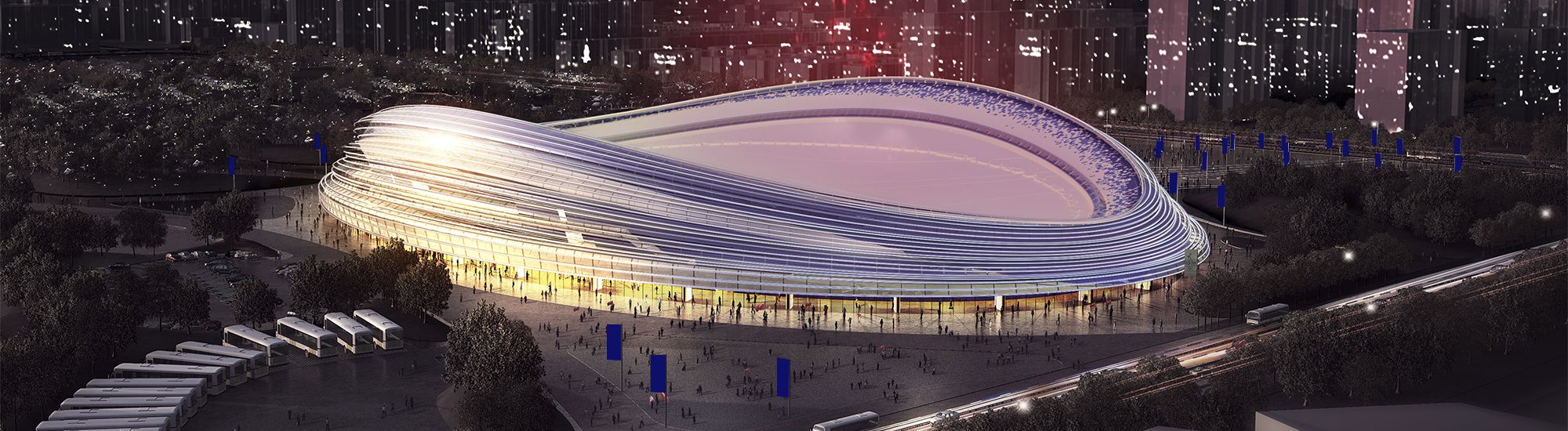

Carrier has won the bid for the transcritical CO2 ice making system for the National Speed Skating Oval, the “Ice Ribbon” in Beijing, China.

The venue's ice-making system consists of several PowerCO2OL racks with 4 MW max cooling capacity running on the natural refrigerant CO2, which has a low Global Warming Potential (GWP) of 1.

These different racks are designed and manufactured by PROFROID, an entity of the Carrier group, in Aubagne (13).

The modularized semi-industrial system uses CO2OLtec®Evo technology with modulating ejectors and assisted by a CO2 pump.

With more than 30% energy savings compared to a standard transcritical CO2 system, this technology allows to reach an optimized energy efficiency.

This refrigeration system is also used in all types of high energy applications such as medium and large warehouses, distribution centers and food processing sites.

The "ice ribbon" covers an area of about 12,000 square meters, almost equal to the size of a track and field. The divisional control of the ice surface meets the competitive requirements of five major categories of ice sports such as speed skating, short track skating, figure skating, curling and ice hockey.

In an effort to reduce carbon emissions, the National Speed Skating Oval adopted CO2 transcritical ice making technology, a historic first for the Olympic Games. It is the most environmentally responsible ice making technology in the world with a carbon emission close to zero.

The advanced technology can control ice temperature variances within 0.5 degrees. In post-Olympic operation, it can save nearly 2 million kWh of electricity each year, which makes the venue sustainable long term.